Wave soldering machine

Home>Product>Wave soldering machine

Description

1. Energy-saving, lead-free application, meet with environmental protection requirement and user friendly designed

2. Automatic power system, inverter control, automatic board in-load feature.

3. Flux sprayer using transverse Japanese spray nozzle and driving by pneumatic cylinders. PLC controlled, accurate and reliable.

4. Preheating system uses four independent temperature control so as to ensure the excellent heat preservation, temperature uniformity, temperature accuracy in ±2ºC.

5. Titanium solder fingers, high strengthened double v-groove with tin resistant

6. Solder motor adopts imported high frequency conversion motor with independent control, stable performance.

Specifications

|

Model |

SFG-350 |

Solder pot type |

The 4th generation energy-saving tin furnace |

|

PCB size |

Max.50~350 |

Heating process |

Matrix type direct sticking 3-sided heating process, thermal efficiency can reach 95% |

|

PCB Height |

750±50mm |

Solder pot tem. |

Room tem.~350℃、Control precision±1-2℃ |

|

Conveyor speed |

0-2000mm/Min |

Control precision |

±2℃ |

|

Welding angle |

3~7° |

Claw type |

FJ claw/L claw/ customed |

|

Components height |

Max.120mm |

Flux |

Manual |

|

Wave height |

0—18mm |

Tem control method |

P.I.D+SSR |

|

Number of wave |

2 |

Width adjustment |

Manual(standard)/Electric(Option) |

|

Length of heating |

1800MM |

Flux adding |

Automatic |

|

Number of heating |

4stage preheating |

Flux flow |

10~100ml/min |

|

Direction |

L→R or R→L |

Spay nozzle |

Step motor +A-100 |

|

Power of preheating |

20KW |

FLUX recycling |

Pallet recycling |

|

Preheating Tem. |

Room Tem.~250℃ |

Power |

3Phase 5line 380V/3Phase 220V(Option) |

|

Heating method |

Hot air |

Start power |

Max.14kw |

|

Solde type |

LEAD Free |

Normal working power |

Approx.3-8kw |

|

Power of solder pot |

14kw |

Air source |

0.4MPa~0.7MPa |

|

Max solder weight |

Approx.450kg |

Dimension size |

4500*1600*1730(L*W*H) |

|

Solder pot material |

Cast iron enamel |

Weight |

Approx.1500kg |

|

Machine’s Shell |

|||

|

Body structure |

Streamlined shell design, using a thick square pass frame, 2mm thick steel plate bending to make the shell, the bottom of the body has 6 direction wheels, and 6 foot cups for positioning and placement (adjustable body level and height); the front door is an extension Curved tempered glass, maximum viewing angle design |

||

|

Front door structure |

Fully enclosed transparent toughened glass door structure, the glass door is equipped with dual hydraulic gas springs to stretch the cover to ensure the largest operation and maintenance space |

||

|

Backdoor structure |

Magnet with hand buckle detachable structure, maximum maintenance space |

||

|

Top of the body |

Set of explosion-proof lighting |

||

|

Surface treatment |

The whole machine is sprayed with computer white (the glass door frame is sky blue) |

||

|

Spay Parts |

|||

|

Nozzle |

The spray range is adjustable from 20 to 65mm, the nozzle height is adjustable from 50 to 80mm, and the maximum flow rate is 100ml/min. |

||

|

Air system |

Adopt imported filter, control valve and pipe joint, digital display air pressure. The spray air pipe adopts acid and alkali resistant, anti-corrosion SMC air pipe |

||

|

Spray nozzle moving system |

Stepping motor drive, PLC intelligent control, combined control with limit proximity switch and plate entrance light eye, automatic detection of induction spray according to the speed and width of the PCB. |

||

|

Flux recovery system |

The bottom of the nozzle is made of stainless steel bent and formed as a tray to contain waste water and flux, which can be taken out and cleaned at will |

||

|

Flux exhaust filter system |

Ventilation system: stainless steel screen frame and double-layer filter screen, using the characteristics of the fluid to filter and recover excess flux |

||

|

Isolated wind curtain |

Pneumatic air knife blows the excess flux during spraying into the recovery box to prevent the flux from entering the preheating zone. Ensure production safety. |

||

|

Spray box structure |

All stainless steel structure, easy to clean and maintain. High level of anti-corrosion and durable. |

||

|

Preheating parts |

|||

|

Four-stage preheating zone |

1800mm/4 sections of independent temperature control preheating zone can provide adequate preheating adjustment space, can preheat some relatively large PCBs, more complex products, adaptable low solid residue no-clean rosin flux; reduce PCB Board thermal shock, PCB board is heated evenly, which can improve production efficiency. |

||

|

Temperature control method |

Mitsubishi temperature acquisition module, PID temperature control is accurate and reliable, imported thermocouple detection system, with thermocouple abnormal alarm function. |

||

|

Heating parts |

Adopting Taiwan Taiwan Exhibition heating element, fast heating, long life, low thermal inertia; uniform heat in the temperature zone. |

||

|

Preheating power |

Total 22kw |

||

|

Installation mode |

The preheating system adopts a direct pull-out drawer type modular design, which is convenient for maintenance and cleaning. |

||

|

Preheat box cover |

It adopts arc streamline appearance design, and is filled with imported Cissr high-density rock wool to enhance heat preservation effect. |

||

|

Conveyor parts |

|||

|

High-strength wear-resistant guide rail |

SFG special aluminum guide rail uses high temperature and wear resistance, and the special thermal compensation anti-deformation telescopic structure ensures that the guide rail is not deformed and does not fall off the board |

||

|

Rail parallelism |

Two-point synchronous guide rail width adjustment device, high-precision screw rod width adjustment, the width adjustment accuracy is less than 0.2mm, 6-point support, so that the guide rails are parallel and consistent, there is no big or small head, the guide rail installation, do not need to cut off, |

||

|

Adjustment method |

Manual |

||

|

Double hook |

SFG special 1.5MM double hook claw (no deformation, non-sticky tin), thickness of splint≦2.5mm (incoming plate is connected by synchronous chain) |

||

|

C/V speed setting minimum unit |

1mm/min 0-1800mm/min |

||

|

C/V speed deviation range |

Electronic closed-loop control within 0-10mm/min |

||

|

Chain tensioner |

Sprocket adjustment tension |

||

|

Conveyor motor |

Taiwan TCG frequency conversion 90W motor, with overload limiter protection device |

||

|

Solder pot |

|||

|

Tin furnace characteristics |

Specially structured wettability nozzle (50-400mm), flat wave design, the way of feeding the tin is the way of lowering the tin, which can reduce the oxidation of the solder joints, the oxide slag automatically accumulates, it is easy to maintain, and does not produce bleachable tin slag black powder |

||

|

Ultra-low oxidation design |

High-quality tin furnace, good thermal stability, adopts liquid tin flow design principle, reduces the impact oxidation of tin, and greatly reduces the oxidation of tin when welding small PCB boards |

||

|

Economical operation |

Controlled by PLC and photoelectric switch to spray wave function, reduce unnecessary waste |

||

|

In and out of solder pot |

Electric |

||

|

Wave height |

0-18mm |

||

|

Wave motor |

Taiwan TCG high temperature motor, frequency conversion to accurately adjust the peak height, digital adjustment |

||

|

Heating parts |

Adopting Taiwan imported dry-burning resistant stainless steel heating tube, long service life; external matrix heating system, the upper and lower heating of the tin furnace is more accurate, no tin explosion, and multiple reinforcing ribs to resist deformation. Save 40% of electricity, about 30 kilowatts of electricity per day |

||

|

Cooling system |

|||

|

Cooling method |

The use of high-power centrifugal fan to blow upwards for cooling can significantly improve the cavitation and pad peeling problems caused by the formation of lead-free solder eutectic |

||

|

Automatic claw washing device |

|||

|

Imported high-quality micro anti-corrosion chemical pump, double-sided washing claw, propanol as cleaning agent, automatic cycle cleaning chain claw |

|||

|

Control software system |

|||

|

★Automatic fault alarm function: there is a thermocouple abnormal alarm function, ultra-high and low temperature alarm; when preheating or tin furnace failure, heating will be stopped |

|||

|

★The temperature of the preheating zone, the temperature of the tin furnace, the transportation speed, the spraying action, and the forced cooling can be separately controlled |

|||

|

★One week time setting (You can set the automatic power on and off time three times a day, seven days a week) |

|||

|

★There are two emergency systems in the nose and tail of the machine, please press in special and emergency situations |

|||

|

Warranty: |

|||

|

Machine:2 year Heating parts:5 year |

|||

Online Inquiry

Related Products

KXFX0384A00 120 Nozzle

KXFX0384A00 120 Nozzle KXFX037TA00 1002 Nozzle

KXFX037TA00 1002 Nozzle N610017372AC 115AS Nozzle

N610017372AC 115AS Nozzle N210064344AC Panasonic CM402CM602 12mm Feeder Spri

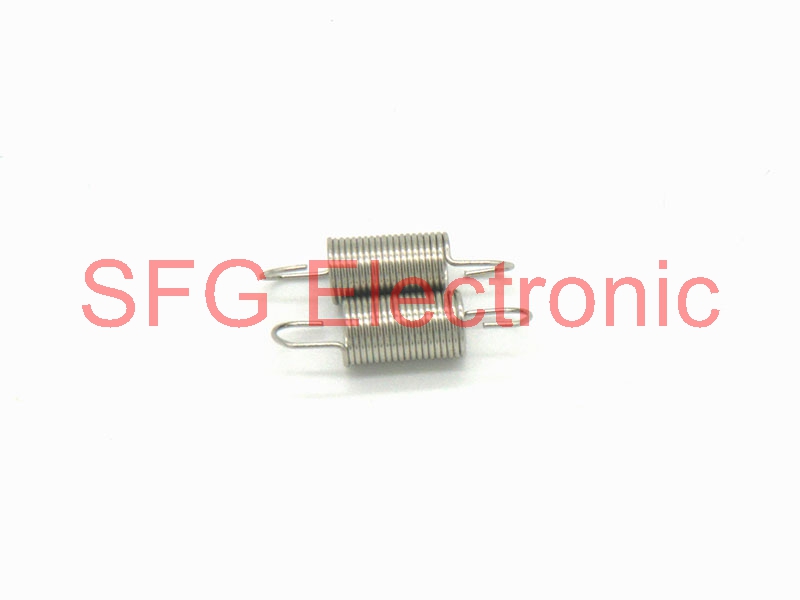

N210064344AC Panasonic CM402CM602 12mm Feeder Spri Panasonic Feeder Spring

Panasonic Feeder Spring N210114131AA Panasonic Cm402 Cm602 Feeder Spring

N210114131AA Panasonic Cm402 Cm602 Feeder Spring KXFA1KEAA00 Panasonic CM402/602 set Screw

KXFA1KEAA00 Panasonic CM402/602 set Screw KXFA1KLAA00 Panasonic CM402/602 8mm feeder PIN

KXFA1KLAA00 Panasonic CM402/602 8mm feeder PIN KXFA1KPAA00 Panasonic CM402/602 NPM feeder parts P

KXFA1KPAA00 Panasonic CM402/602 NPM feeder parts P KXFA1KQAA00 Panasonic CM402 8MM feeder PIN

KXFA1KQAA00 Panasonic CM402 8MM feeder PIN